When using carbendazim, there are several important points to keep in mind. According to the China Pesticide Network, here are four key considerations:

1. Most carbendazim products available on the market come in 50% wettable powder or 40% emulsifiable concentrate forms. Regardless of the form you choose, it's crucial to check the expiration date. The best results are achieved when the product is within one year of its production date. If it has expired, you may need to increase the dosage, but if it's beyond this period, it may no longer be effective and should not be used.

2. Carbendazim is not very effective against Mucor and Rhizopus species. To improve its performance, adjust the pH of the culture medium to a slightly higher level, which can help suppress the growth of these fungi. Since carbendazim is resistant to high humidity, it’s recommended to use sterilized substrates for fermentation. Species like Tremella fuciformis, fungus, and Hericium erinaceus are particularly sensitive to carbendazim, so it's best to avoid using it around them.

3. When mixing carbendazim with other substances, pay close attention to the concentration. Typically, a 50% wettable powder formulation should be used at a rate of 0.1% of the dry weight of the material to effectively control bacterial growth. Using too much can increase costs and negatively affect mycelial growth, potentially leading to contamination of the fruiting bodies. Always dissolve the product thoroughly in water before mixing, and ensure the mixture is well combined to prevent uneven distribution or spot contamination.

4. Carbendazim is prone to degradation in alkaline environments, so it should never be mixed with lime. Storing a mixture of carbendazim and lime for extended periods is also not advisable. Furthermore, repeated use of carbendazim can lead to the development of resistant strains. To avoid this, it's recommended to rotate with other fungicides periodically. This helps maintain the long-term effectiveness of your fungal control strategy.

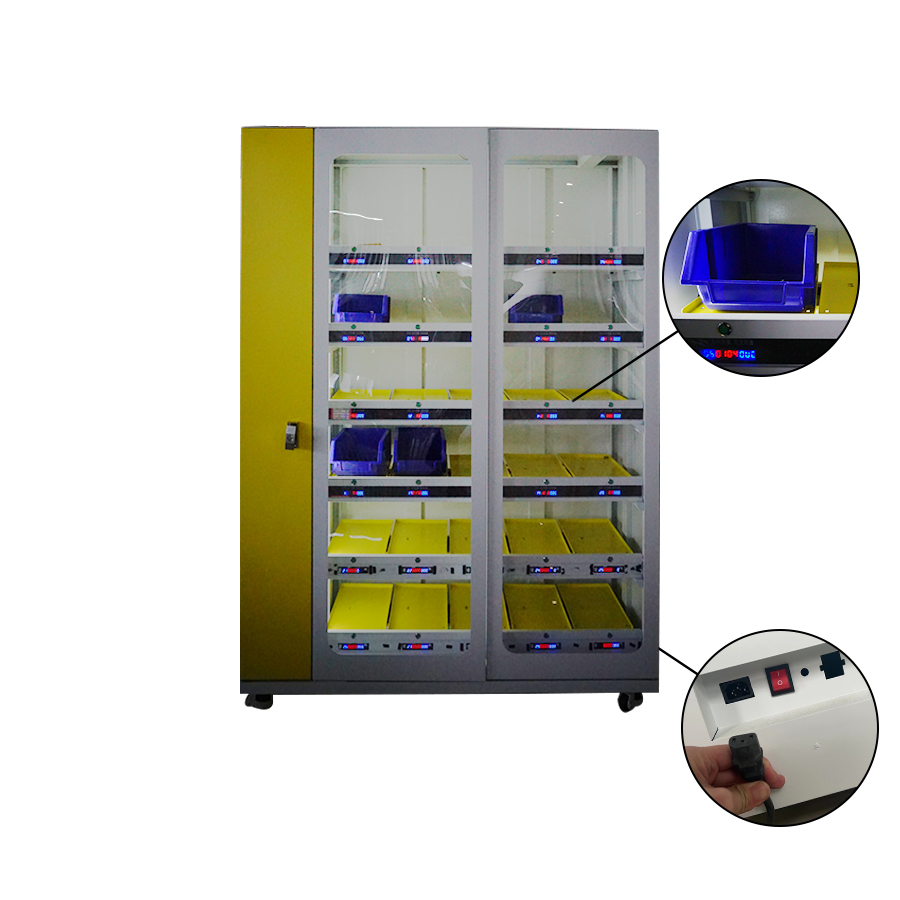

Weighing Cabinet

Enclosure: Weighing cabinets create a contained environment around the weighing balance, preventing hazardous materials from escaping into the laboratory.

Ventilation: Most weighing cabinets are equipped with ventilation systems that draw air into the cabinet, filter it, and exhaust it to the outside or recirculate it within the cabinet. This helps to maintain a safe and clean working environment.

Safety glass: The front panel of a weighing cabinet is typically made of safety glass to provide visibility while protecting the operator from potential hazards.

Ergonomic design: Weighing cabinets are designed to be comfortable and easy to use, with features such as adjustable height and tilt.

Built-in features: Some weighing cabinets may have additional features, such as built-in lighting, power outlets, and storage compartments.

Benefits:

Safety: Weighing cabinets protect the operator and the laboratory environment from exposure to hazardous materials.

Accuracy: The controlled environment within a weighing cabinet can help to ensure accurate and precise weighing results.

Compliance: Weighing cabinets are often required to comply with safety regulations and standards in industries such as pharmaceuticals, chemicals, and research.

Efficiency: By providing a dedicated space for weighing operations, weighing cabinets can improve efficiency and productivity in the laboratory.

Applications:

Pharmaceutical industry: Weighing cabinets are essential for handling and measuring pharmaceutical ingredients, ensuring product quality and safety.

Chemical laboratories: These cabinets are used for weighing chemicals and other hazardous substances in research and development settings.

Research laboratories: Weighing cabinets are valuable tools for scientists conducting various experiments and analyses.

Quality control: In industries where precision weighing is critical, such as food and beverage manufacturing, weighing cabinets are used for quality control purposes.

Types of Weighing Cabinets:

Standard weighing cabinets: These are general-purpose cabinets suitable for a wide range of applications.

Powder weighing cabinets: Designed specifically for handling powders, these cabinets often have specialized ventilation systems to prevent the spread of airborne particles.

Hazardous substance weighing cabinets: These cabinets are equipped with advanced safety features to protect operators from exposure to highly toxic or hazardous substances.

Factors to Consider When Choosing a Weighing Cabinet:

Safety requirements: Consider the specific hazards associated with the materials you will be handling and choose a cabinet that meets the appropriate safety standards.

Ventilation system: Evaluate the ventilation system to ensure it is adequate for your needs and complies with relevant regulations.

Size and capacity: Select a cabinet that is large enough to accommodate your weighing equipment and the materials you will be handling.

Ergonomics: Ensure that the cabinet's design is comfortable and ergonomic for the operator.

Additional features: Consider any additional features that may be beneficial, such as built-in lighting or power outlets.

By investing in a high-quality weighing cabinet, you can create a safe and controlled environment for your precision weighing operations, ensuring accurate results and protecting the health and safety of laboratory personnel.

Product color: White yellow (customizable)

Capacity: 30 scales

Freight lane type: 6 floors * 5 lanes

Weighing sensor: A single weighing position can weigh up to 20 kg, a small weighing capacity of 5g, and an error of 1gram

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ

tool tracking, hazardous materials, precision weighing

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com